G G Automotive Gears Limited Stock Ggauto

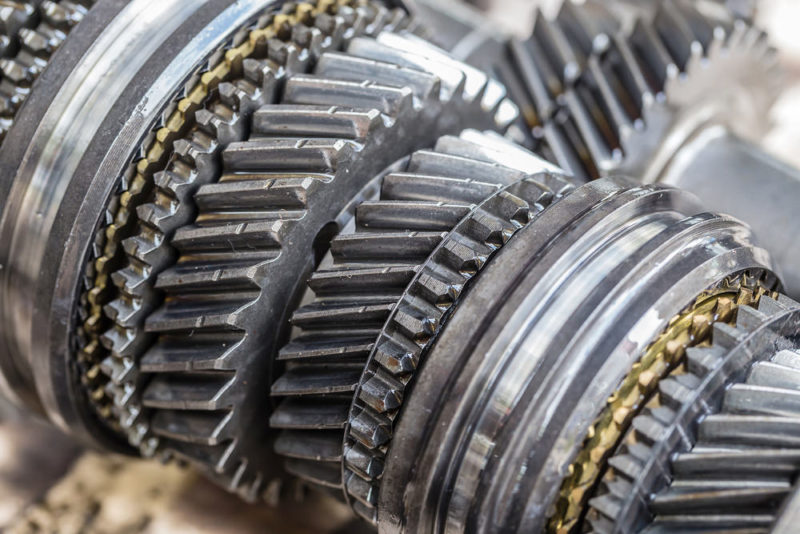

EV drive planetary gears refers to the gear techniques used in EVs with a number of electric motors to transmit power from the motor to the wheels. Planetary gears encompass a solar gear, a ring gear, and planet gears that rotate across the solar gear and mesh with the ring gear, offering a compact and environment friendly approach to obtain totally different gear ratios. In summary, epicyclic gear trains offer a flexible technique of controlling movement and energy distribution in varied mechanical techniques. Their compact design and adaptability make them valuable components in engineering applications that require exact velocity management, direction adjustments, or torque multiplication. In abstract, compound gear trains are important parts in mechanical techniques where a extensive range of speed and torque adjustments are required. Their capability to provide precision and management makes them invaluable in various industrial and automotive applications.

Additive manufacturing offers many alternatives for gear manufacturers. Designers can begin to consider things they have always wanted to have the ability to do but have been hindered by typical manufacturing processes. Additive supplies the chance to introduce inner cooling or lubrication channels that let you put the lubrication in the precise place that might be most helpful to the heavy-load utility. Additive also can help reduce gear system inertia by way of new designs which are tough to manufacture conventionally. Designers can enhance the sturdiness via the utilization of multiple optimized supplies in a single part.

Common materials used for gears include steel, cast iron, aluminum alloys, and superior composites. Manufacturers must balance factors such as power, put on resistance, thermal conductivity, and value to optimize gear performance and meet stringent business standards for reliability and efficiency. The Asia-Pacific region, significantly China, is poised to steer the automotive glass market, pushed by sturdy demand for automotive merchandise within the area. With international locations like India and China witnessing continued progress in vehicle production and manufacturers focusing on increasing their capacities, the demand for automotive elements is anticipated to escalate further. For occasion, China is projected to annually promote roughly eighty million electrical autos in the near future, highlighting the region’s significance within the automotive sector. In the automotive trade, gears are basic to the operation of just about every type of auto.

We are absolutely dedicated to your success from the second you first contact us for a quote to the final supply of the product. We attempt to go above and past to make sure your satisfaction and delight ourselves on delivering outcomes that exceed your expectations. When you work with us, you can trust that we are devoted to your success. Thank you for contemplating us as your go-to associate for precision gear manufacturing. G. G Automotive Gears was integrated in Feb. ‘seventy four as a non-public limited company, was converted right into a public limited firm in 1994. The company began manufacturing gear field housing and other sort of housing for automobile vehicles in 1978.

Cardan Shaft

Given the unique efficiency requirements of electric and hybrid drivetrains, these autos necessitate specialized gear techniques. East Asia and South Asia & Pacific are main regional markets for automotive tools. Advanced supplies like high-strength steel and composites are being more and more integrated into gear production to assist the automotive trade’s pursuit of enhanced efficiency and sustainability. These materials automotive gears offer superior efficiency, lowered weight, and enhanced sturdiness, aligning with the trade’s aims. Dr. Arjun Patel is a distinguished professional in the automotive trade, holding superior degrees in Automotive Engineering and Mechanical Engineering. His expertise spans automotive market dynamics, technological advancements, and sustainable practices.

How To Change Gears In A Conventional Automated

The composition of reinforcement with 6061 aluminium matrix is SiC-7.5% and Al2O3-2.5% respectively. The synthesised composite casting is machined using EDM to organize specimens for varied tests. Microstructure research was carried and the microstructure images show the existence and dispersion of reinforcement particles in the metal matrix. The hardness of the specimen is examined using Vickers hardness tester and found considerable improve when evaluate with mother or father alloy Al 6061. Also mechanical and tribological properties of hybrid Aluminium metal matrix composite had been employed. To avoid enormous material wastage and to achieve absolute accuracy, wire-cut EDM course of is capitalised to engrave the specimen as per required dimensions.

Manufacturing Processes Of Transmission Shafts

As the turbine spins, the shaft spins, sending power to the first planetary gear set of the transmission. Alright, so the torque converter is what permits or prevents energy from the engine to be transmitted to the transmission and what multiples torque to the transmission to get the automotive going from a dead stop. Time to have a look at the components of the transmission that allow the automotive to shift mechanically. This causes the engine to spin faster, which causes the torque converter pump to spin faster.